Optimal R32 Refrigerants and Recovery Solutions

R32 Refrigerants and R32 Recovery Unit

Difluoromethane, another name for R32 refrigerants, is a member of the HFC family of refrigerants used in air conditioning equipment. CH2F2 is its chemical formula. Due to its reduced Global Warming Potential (GWP), this gas is positioned to displace other gases like R-410A and R-407C as the preferred option. Discover more about R32 refrigerants and the step by step refrigerant recovery process in this article.

While switching to R32 refrigerants may not seem critical, many businesses are moving toward items with minimal GWP. R32 is a great substitute for the well-liked R410A, and many top manufacturers already produce R32-compatible machinery.

To ensure compliance with environmental regulations, understanding the step by step refrigerant recovery process is essential. This involves safely extracting refrigerant from HVAC systems, filtering and storing it in contamination-free tanks, and preparing it for reuse or proper disposal. By following this process, technicians can minimize environmental impact while maintaining system efficiency.

By 2025, systems using high-GWP refrigerants (above 750) will be phased out. With R410A's GWP exceeding 2,000 and R32's much lower GWP of 675, the future of refrigerants is clear.

GLOBAL WARMING

The HVAC industry's participants are searching for better refrigerants due to the revelation of the glasshouse implications of the refrigerants used to replace ozone depletion gases. The globe is struggling with the critical issue of global warming, and the planet's average temperature has been rising.

It led several manufacturers to start planning the phase-out of refrigerants like R-410A, R-407C, and R-134A in favour of lower GWP substitutes like R32. It has a -51 °C boiling point.

Since 2013, most newer items in Japan have gradually switched to R32, which operates with 78 percent less refrigerant than R-410A.

R1234yf and R1234ze are other refrigerants that may be used in the future. In terms of performance and operating circumstances, it is fairly comparable to R-410A. Since this gas falls within flammability rating A2 (ISO 817:2014), caution must be exercised when utilising it.

CHALLENGES

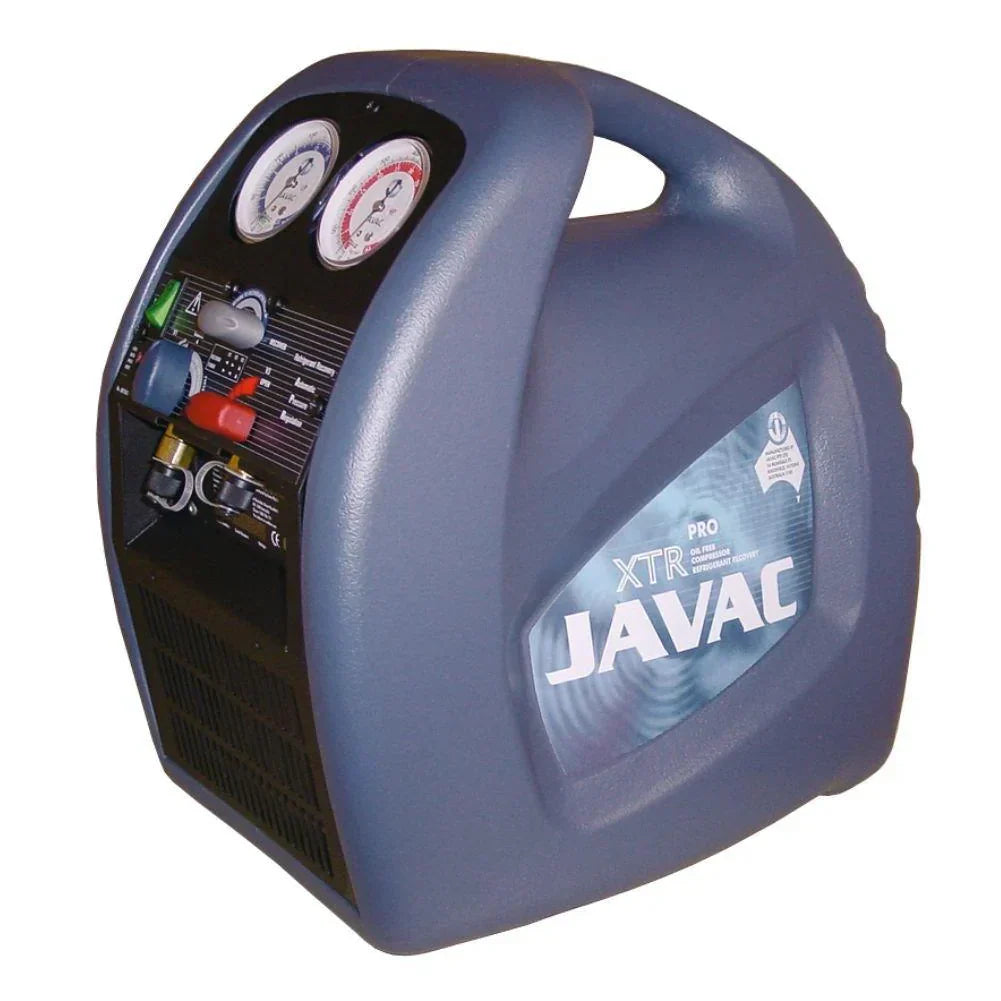

Robinair Portable Refrigerant Recovery Machine Rg6000

While there is a large supply of R32 in Australia, the majority of the cylinders currently in use do not meet the 6000kPa requirements. Cylinder availability depends on finding cylinders with the appropriate pressure rating and deciding on the sort of valve outlet installed on the cylinders.

To ensure compliance with the Australian Dangerous Goods Code, Heatcraft is now examining its branch refrigerant storage facilities and handling processes (ADG code).

Please read the product information label, equipment manual, and applicable regulations and procedures before using R32 refrigerant.

WHY MANUFACTURERS ARE SWITCHING TO R32

Manufacturers of air conditioners decide whether to switch to a new refrigerant for various reasons, including cost, safety, energy efficiency, and environmental impact. Due to the Montreal Protocol, numerous nations are phasing out HCFC 22, an ozone-depleting chemical. HCFC 22 continues to be the main refrigerant in many countries. Reduced use of high Global Warming Potential (GWP) refrigerants is the main force for switching to a new refrigerant in nations where HCFC-22 has already been phased out.

There are several different low GWP refrigerants to choose from. These include C02, Ammonia (R717), Propane (R290), HFC 32 (or R32), HFO 1234yf and HFO mixes, and HFC 32 (or R32) (R744). Unfortunately, none of these alternatives perfectly meet all four essential requirements for a refrigerant—the environment, energy efficiency, safety, and economy—. Each refrigerant has advantages and disadvantages that differ according to the target product.

According to these makers, HFC 32 has been chosen as the best option for usage in several significant air conditioning devices.

WHAT IS THE WORKING PRESSURE OF R32 REFRIGERANT?

R32 has a working pressure between 12 and 26 Bar (174-377 Psi). We should note that even though R32 and R410A have identical operating pressures, the former has a better capacity due to its improved ability to interchange heat load.

Both manufacturers and users should be aware of a gas's working pressures. Only somewhat more force is required for the new refrigerant than for R410A. Would new hoses and gauges be needed for the equipment to work with R32?

Switching between the two refrigerants is simple because of their similar working pressures. The R410A platform may serve as the foundation for new R32 equipment.

The pressure ratio of R32 is a bit higher than that of R410A. The pressure ratio and discharge temperature are both impacted by the isentropic exponent.

R32 has a working pressure between 12 and 26 Bar (174-377 Psi). It's best to note that even though R32 and R410A have identical operating pressures, the former has a better capacity due to its improved ability to interchange heat load.

IS R410A BETTER THAN R32?

R32 and R410a refrigerants are currently utilised in place of R22 in household air conditioners. The two refrigerants differ in the following ways:

Environmental Protection

R32 has a negligible ozone depletion potential (ODP) and an average global warming potential (GWP). Although R32 refrigerants are easily explodable, they do not harm the ozone layer. Although the relative injection amount is less, its atmospheric duration is 5.6 years.

Safety

R410a and R32 are both inert and non-toxic gases. R32 has a low limit of combustion, though. R410a, on the other hand, can burn and has a high temperature. Here is why a comparison of R410a and R32 flammable is crucial.

So it's best only to recharge ACs between 2p.

Thermal Properties

R32 has a higher system operating pressure than R410a, but the biggest gain is only 2.6 percent. R32 rises to 35.3° C when the temperature reaches its maximum, surpassing R410a.

Cyclic Performance

A shortcut to learning additional variations between these refrigerants is to compare the electricity usage of R410a and R32. The system cooling efficiency of R32 is 12.6 percent larger than R410a in terms of theoretical cycle performance. Additionally, R32 has higher power requirements, an energy efficiency ratio, and an overall capacity for energy savings than R410a.

R32 REFRIGERANT RECOVERY

Direct recovery and push/pull are the two most common techniques.

Even though the technology for recovering refrigerant has advanced significantly over the past 25 years, many HVAC/R specialists still complain that it takes a while to complete this task during service visits. Professionals may be tempted to vent refrigerant rather than recover it when time is of the essence. Any such shortcut is a grave error.

Why Do Refrigerants Need Recovery Machine?

Refrigerants play a major role in the heat transfer process that makes air conditioning and heating devices possible. Some of the most popular refrigerants include hydrofluorocarbons (HF), hydrochlorofluorocarbons (HCFCs), and chlorofluorocarbons (CFCs) (HFCs). Since they worsen the risk of global warming and aid in the depletion of the ozone layer, the Environmental Protection Agency (EPA) is already phasing out these refrigerants over the past few years. By Section 608 of the Clean Air Act, the government has also forbidden technicians from purposefully or knowingly venting environmentally harmful refrigerants. The recovery of CFC, HCFC, and HFC-containing refrigerants rather than their venting is required under Section 608.

Civil fines and criminal prosecution are two possible outcomes for breaking the Clean Air Act. An Ohio HVAC worker who illegally vented R-22 received a sentence of more than four years in prison and a $29,045 fine as recently as 2016.

In addition to following the law, recovering refrigerants has other significant benefits. As fewer toxic refrigerants are introduced into the environment, it is advantageous. HVAC/R enterprises can increase their earnings by selling the recovered refrigerant to reclamation firms as R-22 supplies continue to decline.

HOW TO RECOVER REFRIGERANT?

Getting EPA Section 608 Technician Certified is the first step in legally recovering refrigerants. Any technician working on HVAC/R equipment must possess one of the four kinds of certification before adding or removing refrigerant. Service of small appliances falls under Type I, high-pressure heating and cooling systems fall under Type II, and low-pressure devices like chillers are under Type III. Types I through III are covered under the universal certification. Additionally, the EPA must certify the tools that professionals use to recover or reuse refrigerants.

WHAT YOU'LL NEED IN AN R32 REFRIGERANT RECOVERY

To link hoses between an Ac unit, recovery machine, and recovery tank, HVAC gauges are a basic requirement.

HOW TO USE A RECOVERY UNIT

- Disconnect the gauges from the unit to be recovered from and linked to its high and low sides. Blue moves to the low side while red moves to the high side.

- A drier should be positioned here to assist keep pollutants out. The yellow centre hose connects to the suction line of the recovery machine labelled IN.

- From the recovery device, a single pipe leads to the recovery tank.

- Place the tank on a scale to gauge the amount of refrigerant extracted from the unit and prevent overfilling the recovery tank. You may only fill a tank to its legal maximum of 80%.

- The air in the hoses is purged when everything is connected. Do this by opening all of the valves from the unit to the tank (only close the tank valve). Then, allow air to push out of the hoses. It will only happen for a brief period. Retighten the connection to the tank after a short period during which you may hear air escaping from the hose at the tank. Due to the pressure of the refrigerant, it will force the air into the lines.

- The recovery unit is ready to be powered on once the lines have been cleaned. All valves, including the recovery tank valve, should be open. Then, turn on the recovery machine.

- As the refrigerant enters the recovery tank, you should notice a decrease in pressure at the HVAC gauges and recovery machine. To avoid overfilling the recovery tank, keep an eye on the scale. You should never fill a tank over 80% of its capacity. The recovery device should be running until the low side of the recovery machine hits 0 psi. Avoid going below 0 psi since you will be sucking air if there is a leak. When they hit 0 psi, most modern recovery machines will immediately shut off.

- You must clean the recovery machine once the pressure has dropped to 0 psi. To do this, turn the recovery machine's high red and low blue side purge valves. Then, keep an eye on the recuperation machine's gauges. The recuperation machine should shut off once the downside has transitioned from high to low.

- You're finished when you close every valve, including the one for the recovery tank.

TIPS FOR A SMOOTH REFRIGERANT RECOVERY

- Identify the refrigerant you are recovering. It will reduce cross-contamination and assist you in making plans for the necessary recovery tools. Additionally, it will save the expense of disposing of mixed refrigerants.

- Use the shortest hoses appropriate for the task while keeping an eye on your hoses. Longer hoses lengthen the recuperation period. Eliminate all limitations in the hoses. Better hoses than self-sealing hoses have ball valves on the ends. When feasible, remove Schrader core valves from service ports. To prevent contamination, maintain your recovery hoses from your regular servicing hoses.

- Recovery will be aided by a recovery cylinder that has been completely evacuated. Before using the recovery cylinder, always evacuate it to prevent leaks. Always use an in-line filter dryer to recover refrigerant.

- Use the liquid push-pull recovery technique when working with a lot of refrigerants. Always remove the liquid from the system before recovering the last of the vapours. It will considerably hasten the process of recovery. Consult the manual for your equipment for details on liquid push-pull procedures.

- The climate impacts the rate of recovery. Extreme cold or hot conditions might harm recovery rates.

- Always employ the appropriate recovery equipment for the task. An HVAC recovery machine with a lower capacity than what is needed for the work will break down sooner.

- To completely remove the refrigerant when recovering R-410A gas, recovery equipment with high pressure and temperature capabilities is required.

- The technician handling the refrigerant recovery on a CFC or HCFC refrigeration or aircon system must confirm that the appliance has been evacuated to the proper vacuum levels before you can open the system.

FINAL THOUGHTS

When a refrigerant remains in a system, you must use a recovery machine on an HVAC unit.

For instance, recovering the refrigerant would be necessary before changing the component if a compressor needed to be changed.

You can take further steps to hasten recovery, such as switching on the blower motor to prevent the liquid from freezing.

Check out R32 recovery units from HVAC Shop in Australia!

Mixing refrigerants is never a good idea. Keep R-22, R134, and R-410 apart from one another. If the refrigerant returns to the system you withdrew from, old and new refrigerants shouldn't be combined.